Article Sections

- Taiwan High-Tech Fire Retardant Clothing Supply - Taiwan K.K. Corp.

- KANOX® – Fire Retardant, Flame Retardant, Heat Insulation, Chemical Resistant, Anti-Static Fabric

- MAZIC®-- Fire Retardant , Flame retardant, Work Wear fabric, Comprising Aramid Fibers, Viscose, Protex series Make High Performance Protection

- Fire Retardant, Heat Insulation, High Tear/Tensile Strength, User/Environmental Friendly Fabric

- Fire Resistant Clothing Made With Blood-Borne Pathogens Resistant Fire Retardant Fabric, EN469 Certified

- EN469, SGS Certificated Fire Retardant Clothing

- 100% Preoxidized Anti-Static Fire Retardant Fabric & Tested Aircraft Fireblocker

- 2kg Ultra Light Weight Fire Fighting Suit Supply - Taiwan K.K. Corp.

- Preoxidized PAN Blended Fire Retardant Fabric With High Strength

- KANOX ADVANCE Fire Protective Clothing vs NOMEX

- Contact a Taiwan Fire Retardant Fabric Manufacturer - Taiwan K.K. Corp.

- Taiwan K.K. Corp. Privacy Policy

KANOX® – Fire Retardant, Flame Resistant, Heat Insulation, Chemical Resistant, Anti-Static Fabric

MAZIC – Fire Retardant Clothing Made With Flame Resistant Fiber Blends Comprising Modacrylic Fibers

Taiwan K.K. – Total Protective Fire Retardant Clothing Solutions

KANOX® Fabric -- flame resistant, heat-insulation, Anti-static Fire resistant Fabric, user and environmental friendly

Taiwan K.K. Corp. is a fire resistant fabric leader in providing protective garments for firefighter, special army, air force, pilot, and industrial workers of refinery, gas, cement, metal, and welding. Taiwan K.K. owns a big production plant to provide one-stop service with total integration from inherently fire resistant fabrics to high performance firefighter turnout gear and protective clothing. The fire retardant fabric they've developed, KANOX® and MAZIC®,are both tested and certified, which is now sold internationly with solid reputation.

After flamed, KANOX® fire resistant fabric has limited damages compare to other fire resistant fabrics that are available in the market. Flame resistance, heat resistance, thermal resistance, tensile strength, and water vapour resistance are often the determining factors in choosing fire resistant fabrics, and KANOX® fire resistant fabric has all the characters.

Properties of KANOX®

| Properties | Test method | EN 469:2005 performance requirements | KANOX-HM02RP results obtained |

|---|---|---|---|

| Flame Spread | EN ISO 15025:2002 Procedure A | EN533 Index 3. No flaming to edge. No hole formation. No flaming or molten debris. Mean afterflame ≤ 2s. Afterglow not to spread. |

EN533 Index 3. No flaming to edge. No hole formation. No flaming or molten debris. Mean afterflame ≤ 2s. Afterglow not to spread. |

| Heat Resistance | ISO 17493:2000* at 180°C | Materials shall not ignite or melt. Shrinkage ≤ 5%. |

Materials did not ignite or melt. Shrinkage < 1%. |

| Tensile Strength | EN ISO 13934-1:1999 | ≥ 450N | ≥3000N |

| Tear Strength | EN ISO 13937-2:2000 | ≥ 25N | ≥ 150N |

| Dimensional Change | ISO 5077:1984 | Max ± 3% (- = shrinkage) | ≤ 2% |

Thermal Protection Performances (TPP) is composite measures of four layers of turnout gear. The higher TPP value you see, the higher thermal protection performance it is. NFPA 1971 norm requires a TPP value of no less than 35. KANOX® fire resistant fabrics rate TPP value 45-47, much higher than NFPA 1971 requirement and most fire resistant fabrics in the market.

KANOX® fire retardant fabric is a flame retardant fabric with 50 to 60 L.O.I., and its light weight and outstanding thermal stability has made it applicable for making unique turnout gear.

Limited Oxygen Index (L.O.I.)

Limited Oxygen Index (L.O.I.)Flame retardant is generally measured by the highest Limited Oxygen Index, the amount of oxygen needed to support combustion. The higher the LOI value, the more flame resistant the fire retardant material. KANOX® fire retardant fabric has a LOI of over 50 that is much higher than others.

As you can see, KANOX® fire retardant fabric is tested to have higher L.O.I (50-60) than NOMEX and PBI. And so the degradation temperature of fire retardant fabrics, KANOX® fire retardant fabric's temperature appeared to be higher than PBI and NOMEX.

Limiting Oxygen Index (L.O.I.) of Fire Resistent Fibers

Limiting Oxygen Index (L.O.I.) of Fire Resistent Fibers Degradation Temperature

Degradation TemperatureThe degradation point is the point where the fire retardant fabric loses its structural integrity and breaks open. The higher the score, the better it is. KANOX® fire retardant fabric has the highest degradation temperature, which means its traditional protection is also outperforming.

Heat degrades fire resistant fibers at different rates depending on the fiber type, atmospheric conditions and time of exposure. Temperature resistance fire retardant fabric's performance can be determined by its thermal protection performance. A fire retardant fabric should have the ability to slow down the burning rate than others, especially when exposed to heat and flame such as firefighters. When the firefighters exposed themselves in the high temperature, the higher degradation temperature of fire retardant clothing means the slower cauterization. KANOX® fire retardant fabric offers degradation temperature up to 1200 degree Fahrenheit, which is much higher than PBI and NOMEX.

Degradation Temperature of Fire Retardant Fabrics

Degradation Temperature of Fire Retardant FabricsKANOX® fire retardant fabrics supply better heat stability and enhance insulation at light weights as the most conventional fire retardant materials. The fire retardant fabric offers an exclusive heat blocking achievement, little weight, TPP and total heat loss with high L.O.I. level to prevent people from fire injury.

Ultimate in thermal protection

| Tg | Tm | Tp | L.O.I. | |

|---|---|---|---|---|

| KANOX® | - | - | 640 | 55 |

| Meta-aramid | 275 | 560 | 410 | 28.5 ~ 30 |

| Para-aramid | 340 | - | 590 | 29 ~ 31 |

| PBI | 400 | - | 500 | 40 ~ 42 |

| Cotton | - | - | 350 | 17 ~ 20 |

| Wool | - | - | 245 | 22 ~ 25 |

| Nylon 6.6 | 50 | 265 | 403 | 20 ~ 21.5 |

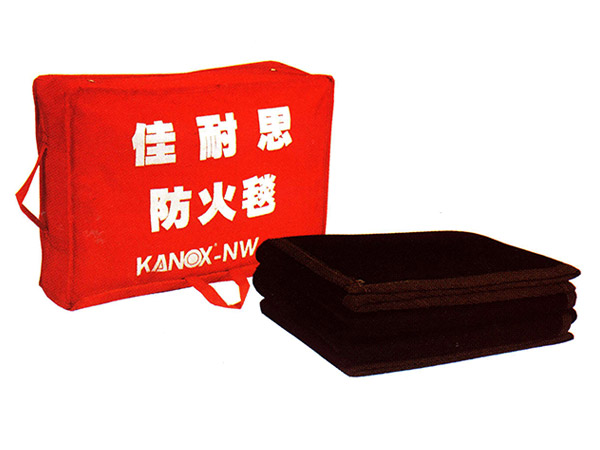

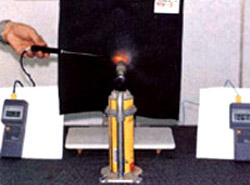

KANOX®-NW3 thermal insulation material is 100% Pre-Oxidized PAN non-woven fabric with 3mm thickness and 450g/m2 weight. It is light weight, non-fiberglass (irritating to skin), non-asbestos (carcinogen), no chemical treatment adding. It is tested in room temperature at 34 degrees with direct flame contact (ave. 1020°C) of sample material.

An initial temp of 34°C and end temp of 91°C were measured after 3 min, direct flame contact, No burn-through or melting on the material. KANOX® fire retardant fabric proves its good flame resistance.

Infrared Rays Reflectance and Moisture Absorption

Infrared Rays Reflectance and Moisture Absorption

Certification of KANOX® Fire Retardant Fabric

KANOX® fire retardant fabric has passed tests and obtained certifications to prove its great performances. (No melting no burn-through, no shrinkage after 1 minute). It is EN 470-1, EN 531, EN 11611, EN11612, EN15384, EN1149, EN 469, UL listed passing NFPA-1971 standards.

-

KANOX® Fire Retardant Fabric - Types of Applications

- Fire Fighting Hood

- Fire Fighting Helmet

- Fire Fighting Boots

- Fire Fighting Gloves

- Fire Retardant Clothing

- Forest Fire Fighting Clothing

- Fire Resistant Clothing in different fields

- Emergency Fire Blanket / Welding Blanket

- Fire Blocker for airplane interior decoration

KANOX® Fire Retardant Fabric Heat Transfer Test & Result

The table is EN469 test results of four different models of KANOX® Fire Retardant Clothing : Heat Transfer Index (HTI24) is all above 19 seconds, which is much higher than EN469 level 2 requirements – 13 seconds.

The table is EN469 test results of four different models of KANOX® Fire Retardant Clothing

The table is EN469 test results of four different models of KANOX® Fire Retardant ClothingThe table is EN469 test results of four different models of KANOX® Fire Retardant Clothing : Heat Transfer Index (RHTI24) is all above 21 seconds, which is much higher than EN469 level 2 requirements – 18 seconds.

The table is EN469 test results of four different models of KANOX®

The table is EN469 test results of four different models of KANOX®NFPA 1971:2007 Fire Retardant Fabric Thermal Protection Performance

NFPA 1971 defines TPP as "heat absorbed by each unit area when human tissues reach 2nd degree burn injury". The higher TPP index represents that more heat is absorbed, and makes the insulation property better. TPP test of NFPA 1971 uses 2 burners and 6 heat radiation tubes to simulate actual flame and radiation environment in the fire site.

-

NFPA 1971 requires TPP ≥35.5 cal/cm²

- TPP index calculation : TPP = F × T

- F : heat radiation per square centimeter (cal/cm²s)

- T : time that human tissues reach 2nd degree burn injury (s)

-

TPP of KANOX® Fire Retardant Clothing :

- 44.8 cal/cm² (before wash)

- 51.0 cal/cm² (after 5 times wash)

KANOX® Fire Retardant Clothing own excellent Thermal Protection Performance

Fire Resistant Fabric - KANOX® series

| Article No. | Specification | Features | Applications | Color in stock |

|---|---|---|---|---|

| AD02RP | 240±5g/m². Ripstop. Anti-static. |

High strength. Excellent heat resistance. Good abrasion resistance. |

Outer shell of fireman suit. Rescue suit. |

Navy Blue. Royal blue. Orange. Yellow. Red. |

| AD02LCP | 260±5g/m². Jacquard weave. |

High strength. Excellent heat resistance. Good abrasion resistance. Innovative color & pattern. |

Outer shell of fireman suit. Reinforcement. Palm abrasion of Gloves. |

Navy Blue with white dots. Orange with white dots. |

| HM02RP | 240±5g/m². Ripstop (or Twill). |

High tear/tensile strength | Outer shell of fireman suit. Rescue suit. Anti-riot coverall |

Navy Blue. Royal Blue. Yellow. Orange. Red. |

| KANOX-G | 280±5g/m². Twill. Pan-oxidize & high strength fiber. |

Excellent flame & heat resistance. Resistance to metal splash. |

Welding suit. | Dark Green |

| TM02 | 210±5g/m². Ripstop. Anti-static. |

Good flame & heat resistance. | Anti-riot coverall. Industrial workwear |

Black |

| GORNOX | 120±10g/m². Non-woven. |

Good heat resistance | Thermal layer of fireman suit | Yellow |

| * KANOX® and MAZIC® Fire Resistant Fabrics comply with EN531, EN470, EN ISO 11611, EN ISO 11612, ISO 15384, EN469, and/or NFPA1971. More items of KANOX® and MAZIC® fabrics are available upon request. | ||||

- KANOX® Fire Retardant Clothing:

- SUPER ARMOR PREMIUM (TK09AD01 ADVANCE) - Anti-Virus Penetration Fire Fighting Clothing

- SUPER ARMOR ELITE (TK09HM01) - Blood-Borne Pathogens Resistant Fire Fighting Clothing

- SUPER ARMOR ELITE (TK09FM01)- Anti-Static Fire Fighting Clothing

- SUPER ARMOR ELITE (TK09AD01) - High Tear Strength Fire Fighting Clothing

- SUPER ARMOR REV (TK12GA01) – Great Abrasion Resistant & Ultra Light Fire Fighting Clothing

Sections

Send A Fire Retardant Clothing Inquiry

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Exhibitions

INTERSCHUTZ 2015

Date: June 8-13, 2015

Booth: Hall 012 / Stand No. G76

Opening Hour: 9am - 6pm

Venue: Deutsche Messe Hannover

[Read more]

News & Press Release

Visit latest design of fire retardant clothing and fire resistant accessory at Fire India 2013

Visit Quality Fire Retardant Clothing at A+A

Visit fire protection clothing supplier at China Fire

Taiwan K.K. Fire Fighting Garment in Nordic Europe

Taiwan K. K. Corp., is a qualified company to supply PPE to fulfill the requirements.

Ready-eSupport

For LIVE HELP... just click "Live Help Desk", our specialists will be with you in air shortly.

Reference

Firefighter Turnout Gear NFPA 1971 Standard (new edition)

Structural Fire fighter Uniform EN 469 Standard (new edition)

Share

Related Products