Article Sections

- Taiwan High-Tech Fire Retardant Clothing Supply - Taiwan K.K. Corp.

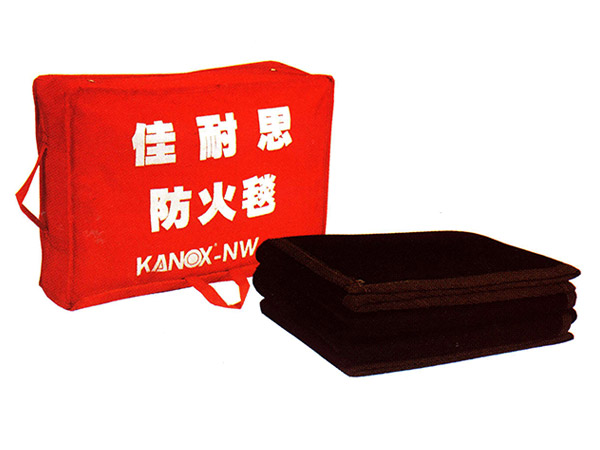

- KANOX® – Fire Retardant, Flame Retardant, Heat Insulation, Chemical Resistant, Anti-Static Fabric

- MAZIC®-- Fire Retardant , Flame retardant, Work Wear fabric, Comprising Aramid Fibers, Viscose, Protex series Make High Performance Protection

- Fire Retardant, Heat Insulation, High Tear/Tensile Strength, User/Environmental Friendly Fabric

- Fire Resistant Clothing Made With Blood-Borne Pathogens Resistant Fire Retardant Fabric, EN469 Certified

- EN469, SGS Certificated Fire Retardant Clothing

- 100% Preoxidized Anti-Static Fire Retardant Fabric & Tested Aircraft Fireblocker

- 2kg Ultra Light Weight Fire Fighting Suit Supply - Taiwan K.K. Corp.

- Preoxidized PAN Blended Fire Retardant Fabric With High Strength

- KANOX ADVANCE Fire Protective Clothing vs NOMEX

- Contact a Taiwan Fire Retardant Fabric Manufacturer - Taiwan K.K. Corp.

- Taiwan K.K. Corp. Privacy Policy

MAZIC®-- Fire Retardant , Flame resistant, Work Wear fabric, Comprising Aramid Fibers, Viscose, Protex series Make High Performance Protection

High Strength MAZIC® Flame Retardant Fabric Comes With Colors

Stronger, Lighter, Safer Fire Retardant Fabric - MAZIC®

MAZIC® Fabric - Modacrylic fiber Blended With High Strength Fiber or Cotton Fiber

Taiwan K.K. Corp. is fire retardant clothing and fabric supplier. Their fabric, MAZIC® and KANOX® are developed for making protective garments for firefighter, special army, air force, pilot, and industrial workers of refinery, gas, cement, metal, and welding.

MAZIC® Fire Retardant fabric series are made of MAZIC® yarn consisting of Aramid, Viscose, Protex series, and/or high strength fiber. This high performance fire retardant fabric is great for making station wears, thermal protective garments, clothing for use in welding and alloy processes. MAZIC® fire retardant fabric series is flame resistant. It has non-melting, non-dripping and non-toxic with self-extinguishing capability. The fire retardant fabric series' light weight and high tenacity come with air permeable, which brings comfortable feelings when wearing it. MAZIC® fire retardant fabric is made of 100% inherently fire resistant rather than chemical treated; it means the fabric providing advanced resistance to fire & heat. The fire retardant fabric series appear various color options including navy blue, orange, olive green, camouflage, grey and red. Customization design is welcome as well.

Protex Series

Protex fiber is flame resistance which does not combust; it is difficult to kindle and has self-extinguishing property. In addition to Protex fiber's fire retardant properties, it has a relatively high durability that is similar to wool. Protex fiber is used in where environment resistance or fire retardant is essential or requested. Protex fibers are soft and comfortable to wear; they do not wrinkle and have great dimensional stability and high elastic recovery, which make them the ability to stay in shape. MAZIC® fire retardant fabric is made of aramid, Viscos, Protex series, and/or high strength fiber; it has great flame resistance characteristics, which provides a comfortable feeling as well.

Station wears, thermal protective garments, fire retardant clothing for use in welding and alloy processes can be made of the below high performance fire retardant fabrics:

Fire protective properoty

| Property | Test | Performance Required | MAZIC®-ST02 | Result | |

|---|---|---|---|---|---|

| Impact of molten metal drops | EN532 | ≥Drops to raise temperature by 40k | No. of drops≥5 | pass | |

| Flame Spread | EN532 | No flaming to the top or either side edge. No holing. No flaming debris. Afterflame ≤2seconds. Afterglow≤2seconds. |

No flaming to the top or either side edge. No holing. No flaming debris. No afterflame. No afterglow. |

pass | |

| Convective Heat | EN367 | Level | HTI | HTI =4.5 | Level B1 |

| B1 | 3-6 | ||||

| B2 | 7-12 | ||||

| B3 | 13-20 | ||||

| B4 | 21-30 | ||||

| B5 | >30 | ||||

| Radiant Heat | EN366at 20KW/m² | Level | T2 | T2 =13secpmds | Level C1 |

| C1 | 8-30 | ||||

| C2 | 31-90 | ||||

| C3 | 90-150 | ||||

| C4 | >150 | ||||

Durable property

| Property | Test | Performance Required | MAZIC®-ST02 | Result |

|---|---|---|---|---|

| Tensile Strength | ISO 5081 | ≥300N | Warp N Fill N > 450N > 450N | pass |

| Tear Strength | ISO 4674 | ≥15N | Warp N Fill N > 70N > 70N | pass |

| Dimensional Change | ISO 6330/5077 | Not to exceed ±3% in either direction (= shrinkage) | Warp% Fill% < ±2% < ±2% | pass |

| ColorFastness-Washing | CNS 1494 L3027 A-2 | - | - | 4 - 5 |

| Color Fastness-Light | CNS 3845 L3074 | - | - | 4 |

High temperature resistance and flame, fire and heat transfer performance are significantly relevant to an industrial worker's life. Only strictly tested and internationally certified fire retardant fabrics can protect lives. According to the difference of function, Heat Transfer is separated as two kinds, one is Heat Transfer-Flame, and the other one is Heat Transfer-Radiation.

- When test the Heat Transfer, EN469:2005 states the time of a temperature rise of 24°C in the calorimeter affecting the materials can't be less than a specific time. That means when a firefighter contacts the flame and heat, the temperature of inner lining of fire retardant clothing rises up; meanwhile, the temperature of his body rises up 24°C from 36°C to 60°C, in such condition, the man will get 2nd degree burn injury. The time that cause a man to get 2nd degree burn injury, we call it as HTI24 and RHTI24.

- Another regulation required the time for a firefighter to get injury from 1st degree burn to 2nd degree burn, can't be less than a specific time.

- Then divided the result as level 1 and level 2. According to the standard (HTI24-12) and (RHTI 24-12), there are regulations to protect firefighters to evacuate safety, will not sacrifice their life.

MAZIC® Fire Retardant Fabric Heat and Flame performance

This introduction is based on EN469:2005 and combined with NFPA 1971:2007 norm for fire retardant clothing. EN 469 fire retardant clothing's Heat & Flame testing includes flame spread test, heat resistance test and heat transfer test.

EN 469:2005 Fire Retardant Fabric Flame Spread and Flame Resistant Requirement

High temperature resistant, high strength fire retardant fabrics support significantly in allowing products to meet these tasks. Fire retardant clothing is facilitated using these flame resistant fibers go far beyond the capacity and knowledge of most people

On fire fighting rescue operations, unavoidable, fire retardant clothing will explore in high thermal temperature, even more, will direct contact flash fire, for this definitely require an extraordinary materials to protect firefighters. EN 469:2005 norm assembly flame resistant fabric needs to posses excellent character of flame resistant and thermal stability. Main requirements are:

-

6.1 Frame Spread

- No flaming to edge

- No hole formation

- No flaming or molten debris

- Mean afterflame ≤ 2s

- Mean flaterglow ≤ 2s

-

6.5 Heat resistance

- Materials shall not melt, drip or ignite

- Every layer shrinkage ≤ 5%

MAZIC® Fire Retardant Fabric Flame Spread Test & Result

EN 469:2005 adopt vertical flame test methods, applying burner flame toward fire retardant clothing outer and inner assembly layers for 10 seconds, to test and check the flame spread data.

-

The statistic below is to show the testing results of EN 469 assembly flame resistant fabrics:

- No flaming to edge

- No hole formation

- No flaming or molten debris

- No afterflame

- No afterglow

KANOX®'s EN 469:2005 technical data sheet (6-1) 6.1 flame spread

KANOX®'s EN 469:2005 technical data sheet (6-1) 6.1 flame spreadMAZIC® Fire Retardant Fabric Heat Resistance Test & Result

According to EN469:2005, it uses an oven to simulate the hot air circulating environment of fire scene. The fire retardant fabric is placed into an oven for 5 minutes, at the specified temperature at 180°C, in order to test if the flame retardant fabric in compliance with every requirements.

-

The picture below is the test summary statistics for KANOX® fire retardant clothing assembly, in accordance with EN469 regulation.

- Outer shell did not melt, drip, or ignite.

- Outer shell shrinkage 0.2%

- Inner lining shrinkage 0.5%

KANOX®'s EN 469:2005 technical data sheet (7-2) 6.5 heat resistance

KANOX®'s EN 469:2005 technical data sheet (7-2) 6.5 heat resistanceMAZIC® Fire Retardant Fabric Heat Transfer Test & Result

In a general condition, the data for HTI24, depends on the thickness of specimen. The thicker specimen makes the HTI 24 data greater.

| Band | HTI limits | Typical assembly | Comments |

|---|---|---|---|

| 1 | 3 to 6 | Single layer | Most single layer fabrics give results of 4 or 5 |

| 2 | 7 to 12 | Double layer, thick single | Covers a wide range of normal multilayer apparel |

| 3 | 13 to 20 | Triple layer, thick double | Specialist firefighting clothing has HTI about 16 |

| 4 | 21 to 30 | Very thick | Specialist heat protective clothing |

| 5 | Over 31 | Extremely thick | Very special applications |

The fire retardant clothing that is used for EN and NFPA generally combined with 3 or 4 multilayer fire resistant materials, and HTI24 data is around 16.

Fire Resistant Fabric - MAZIC® series

| Article No. | Specification | Features | Applications | Color in stock |

|---|---|---|---|---|

| FM02 | 210g/m². Ripstop (or Twill). Anti-static. |

Good abrasion resistance. | Outer shell of fireman suit. Rescue suit, Anti-riot coverall. Industrial workwear. |

Navy Blue. Orange. Red. Sage Green. |

| ST02 | 170g/m². 200g/m². 230 g/m². Twill. |

Good flame resistance. | Industrial workwear. Station uniform. Wildland Firefighting suit. |

Navy Blue. Royal Blue. Yellow. Orange. |

| FV06 | 260g/m². Twill. |

Good flame resistance. Comfortable. |

Rescue suit. Station uniform. Industrial workwear. |

Yellow. Sage Green. |

| SV02 | 190 g/m². Knitted. |

Good flame & heat resistance. Good elasticity. |

FR Undergarment. FR Shirt. |

Navy Blue. Orange. |

| AC02 | 230g/². Knitted. |

Good flame & heat resistance. Good elasticity. |

Fire Hood. FR Shirt, Helmet lining. |

Navy Blue. Black. |

| FM02K | 230 g/². Knitted. Anti-static. |

Good flame & heat resistance. Good elasticity. |

Fire Hood. FR Shirt. Helmet lining. |

Navy Blue. Gray. Grayish white. |

| * KANOX® and MAZIC® Fire Resistant Fabrics comply with EN531, EN470, EN ISO 11611, EN ISO 11612, ISO 15384, EN469, and/or NFPA1971. More items of KANOX® and MAZIC® fabrics are available upon request. | ||||

Sections

Send A Fire Retardant Clothing Inquiry

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Exhibitions

INTERSCHUTZ 2015

Date: June 8-13, 2015

Booth: Hall 012 / Stand No. G76

Opening Hour: 9am - 6pm

Venue: Deutsche Messe Hannover

[Read more]

News & Press Release

Visit latest design of fire retardant clothing and fire resistant accessory at Fire India 2013

Visit Quality Fire Retardant Clothing at A+A

Visit fire protection clothing supplier at China Fire

Taiwan K.K. Fire Fighting Garment in Nordic Europe

Taiwan K. K. Corp., is a qualified company to supply PPE to fulfill the requirements.

Ready-eSupport

For LIVE HELP... just click "Live Help Desk", our specialists will be with you in air shortly.

Reference

Firefighter Turnout Gear NFPA 1971 Standard (new edition)

Structural Fire fighter Uniform EN 469 Standard (new edition)

Share

Related Products