Article Sections

- Taiwan High-Tech Fire Retardant Clothing Supply - Taiwan K.K. Corp.

- KANOX® – Fire Retardant, Flame Retardant, Heat Insulation, Chemical Resistant, Anti-Static Fabric

- MAZIC®-- Fire Retardant , Flame retardant, Work Wear fabric, Comprising Aramid Fibers, Viscose, Protex series Make High Performance Protection

- Fire Retardant, Heat Insulation, High Tear/Tensile Strength, User/Environmental Friendly Fabric

- Fire Resistant Clothing Made With Blood-Borne Pathogens Resistant Fire Retardant Fabric, EN469 Certified

- EN469, SGS Certificated Fire Retardant Clothing

- 100% Preoxidized Anti-Static Fire Retardant Fabric & Tested Aircraft Fireblocker

- 2kg Ultra Light Weight Fire Fighting Suit Supply - Taiwan K.K. Corp.

- Preoxidized PAN Blended Fire Retardant Fabric With High Strength

- KANOX ADVANCE Fire Protective Clothing vs NOMEX

- Contact a Taiwan Fire Retardant Fabric Manufacturer - Taiwan K.K. Corp.

- Taiwan K.K. Corp. Privacy Policy

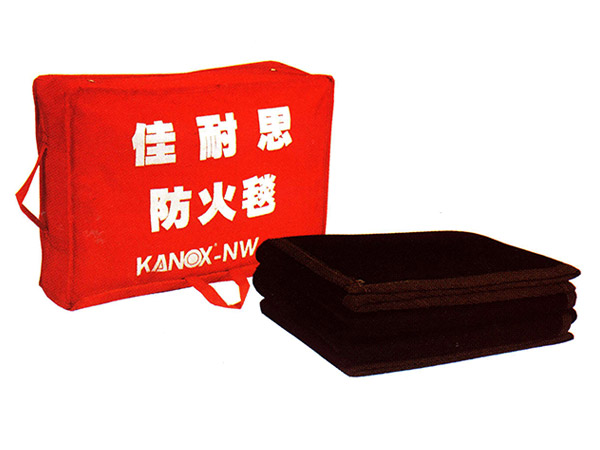

EN469, SGS Certificated Fire Retardant Clothing

100% Plain Fire Retardant Material

Blood-Borne Pathogens Resistant Fire Retardant Fabric

EN469:2005 Certificated Fire Retardant Clothing – ELITE (TK09HM01) Series

-

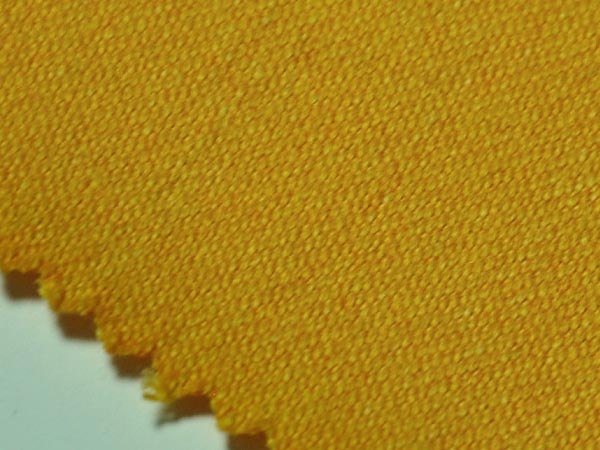

OUTER SHELL MATERIAL: K-HM02RP

- Weight 240 g/m² rip-stop structure (or Twill)

- Color: Navy Blue, Royal Blue, Yellow, Orange, Red

- Features: High tear/tensile strength

- Applications: Outer shell of fireman suit, Fire Retardant Clothing, Anti-riot coverall

-

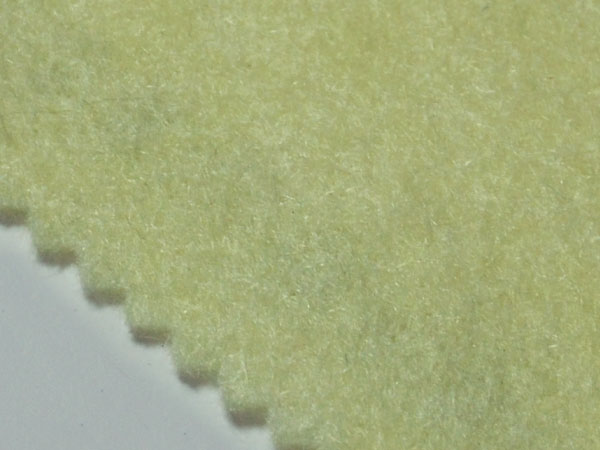

THERMAL LINER MATERIAL: K-GORNOX

- 120 g/m² Non-woven structure

- Color: Yellow

- Features: Good heat resistance

- Applications: Thermal layer of fire retardant clothing

-

MOISTURE BARRIER MATERIAL: F-100SL-PTFE

- SGS Certified, Fluid penetration resistance

-

LINING MATERIAL: M-ST02

- 170g/m², 200g/m², 230g/m², Twill structure

- Color: Navy Blue, Royal Blue, Yellow, Orange

- Features: Good flame retardant

- Applications: Industrial work wear, Station uniform, Wildland Fire Retardant Clothing

The importance of fire retardant fabric selection was demonstrated with the launching of a new fire retardant clothing by one of the leading fire retardant material manufacturers – Taiwan KANOX®. The unique fire retardant clothing series TK09HM01 design is limited-life chemical-protective gas-tight clothing that offers certified protection against fire, virus, chemical, etc. Customized versions for other situations are available. They are EN 469:2005 and NFPA 1971 certified and the moisture barrier fire retardant fabric is SGS tested to prove its great performance.

ELITE (TK09HM01) Series have moisture barrier made of F-100SL-PTFE ; a fire retardant fabric that is SGS certified, which is made to enhance its thermal resistance. Therefore, TK09HM01 fire retardant clothing is suitable for situations that involve viruses such as SARS or AIDS, or chemical and blood, in which contamination isolation is critical.

-

ELITE (TK09HM01) Series Fire Retardant Clothing:

- 4-layer fire retardant fabric construction

- made by self-brands [KANOX®] and [MAZIC®] inherently fire retardant fabric

- good water vapor resistant

- excellent flame retardant performance

- various color choices of fire retardant material

- EN469:2005 compliant, and CE certificated

ELITE (TK09HM01) Series Fire Retardant Clothing- Outer Shell Fire Retardant Fabric - K-HM02RP

KANOX® fire retardant fabric is pre-oxidized fiber used for outer-shell material, hoods and other fire resistant applications. KANOX® fire retardant material will not burn, melt, soften or drip. It is NFPA 1971-2000 approved/compliant (certified) with excellent results in all required tests as well as a number of other widely-accepted industry tests. By many measures, it is the best protective fire retardant clothing at any price.

Outer-shell fire retardant fabric is the first and most important layer of defense in protecting life. KANOX® fire retardant fabric is made from an exclusive blend that in effect "starves the fire" in addition to providing excellent traditional protection against fire. This different approach is proven and is by no means experimental. KANOX® fire retardant fabric borrows from a knowledge base developed in other industries that have even more significant fire resistance issues.

In material science, the strength of a fire retardant material is its ability to bear an applied force without failure. KANOX®'s K-HM02RP has great tensile strength and it is tested using ENISO 13934-1:1999 method. Based on EN 469:2005's ≥ 450N performance requirement, K-HM02RP's ≥ 3000N tensile strength is much higher. Likewise, its tear strength is ≥ 25N, which is better than ENISO 13937-2:2000's standard, ≥ 150N.

K-HM02RP is a fire retardant fabric for outer shell of fire retardant clothing, and is EN469:2005 certified. It is available in various colors (dark blue, yellow and orange); and weights 240 g/m² with rip-stop structure.

Properties of MAZIC®

| Properties | Test method | EN 531, EN 470-1 performance requirements | MAZIC-FM02 results obtained | MAZIC-ST02 results obtained | |

|---|---|---|---|---|---|

| Flame Spread | EN 532:1994 | No flaming to edge. No hole formation. No flaming debris. Mean afterflame ≤ 2s. Mean afterglow ≤ 2s. |

No flaming to edge. No hole formation. No flaming debris. No afterflame. No afterglow. |

No flaming to edge. No hole formation. No flaming debris. No afterflame. No afterglow. |

|

| Convective Heat | EN 367:1992 | Level | HTI | B1 | B1 |

| B1 | 3 - 6 | ||||

| B2 | 7 - 12 | ||||

| B3 | 13 - 20 | ||||

| B4 | 21 - 30 | ||||

| B5 | 30 → | ||||

| Radiant Heat | EN 366:1993 MAthod Bat 20kW/m² | Level | HTI | C1 | C1 |

| C1 | 8 - 30 | ||||

| C2 | 31 - 90 | ||||

| C3 | 91 - 150 | ||||

| C4 | 151 → | ||||

| Impact of molten metal drops | EN 348:1992 | ≥ 15 drops to raise temperature by 40K | Mean 17 drops | Mean 16 drops | |

| Tensile Strength | ISO 5081:1997 | ≥ 300N | ≥ 950N | ≥ 900N | |

| Tear Strength | ISO 4674:1977 MEthod A1 | ≥ 15N | ≥ 100N | ≥ 110N | |

| Dimensional Change | ISO 5077:1984 | Not to exceed ±3% | ≤ 1.5% | ≤ 1.5% | |

ELITE (TK09HM01) Series Fire Retardant Clothing - Moisture Barrier Fire Retardant Fabric – F-100 SL-PTFE

SGS certified moisture barrier is the second layer of the fire retardant clothing, composed mostly of a layer laminated to a fabric substrate. Moisture fire retardant material allows sweat to get away and supplies fluid penetration resistance against blood and body fluids, common chemicals, and water, helping the firefighter stay dry and protected.

| Moisture absorption | |

|---|---|

| KANOX® | 8~12 |

| Natural Slik | 12 |

| Cotton | 8.5 |

| Nylon | 4.5 |

| Polyester | 4.5 |

| Natural Wool | 15 |

| Rayon | 11 |

ELITE (TK09HM01) Series Fire Retardant Clothing 110g Light, Thin Thermal Barrier Fire Retardant Fabric - K-GORNOX

K-GORNOX is the 3rd layer of Fire Retardant Clothing which requires fire retardant fabric to be light, thin, and heat resistant. It is a non-woven fabric that is a fabric-like material made from long fibers, bonded together by chemical, mechanical, heat or solvent treatment.

Thin, light K-GORNOX fire retardant fabric outperforms other fabric providers such as Nomex® IIIA and PBI. K-GORNOX's fire retardant material is tested with result of having more than 50 of L.O.I. (higher LOI values represent better flame redundancy), and it’s degradation temperature of fire retardant fabric is 1200 degrees fahrenheit.

KANOX®'s K-GORNOX is a high quality fire retardant fabric with great thermal protection performance. It has higher thermal protection performance (TPP) than NOMEX® IIIa and PBI.

K-GORNOX is a thermal barrier of fire retardant fabric. Fire retardant fabrics could be used in power, aluminum and cement industries on fire retardant and thermal insulation.

| Thermal Protection Performance (TPP) | ||||

|---|---|---|---|---|

| PBI | NOMEX advance | KANOX ® | NFPA 1971-2000 Req. | |

| TPP | 46-48 | 41-43 | 45-47 | 35 |

| Total Heat Loss (THL) | ||||

|---|---|---|---|---|

| PBI | NOMEX advance | KANOX ® | NFPA 1971-2000 Req. | |

| THL | 288-233 | 215-220 | 228-233 | 130 |

ELITE (TK09HM01) Series Fire Resistant Clothing, Fire resistant Fabric, Lining Fabric- M-ST02

Fire retardant fabric linings are recommended for many projects and for a variety of reasons. When manufacturing fire retardant clothing, the lining is added for a measure of comfort especially for heavier and bulky apparels. Linings in the Fire Retardant Clothing help these kinds of garments close to the skin and make pulling on and off easier.

Aramid fire retardant fabric is extremely durable and stable, and suitable for fire retardant clothing. This fire retardant fabric weights 150g/m² and comes with dark blue.

- KANOX® Fire Retardant Clothing:

- SUPER ARMOR PREMIUM (TK09AD01 ADVANCE) - Anti-Virus Penetration Fire Fighting Clothing

- SUPER ARMOR ELITE (TK09HM01) - Blood-Borne Pathogens Resistant Fire Fighting Clothing

- SUPER ARMOR ELITE (TK09FM01)- Anti-Static Fire Fighting Clothing

- SUPER ARMOR ELITE (TK09AD01) - High Tear Strength Fire Fighting Clothing

- SUPER ARMOR REV (TK12GA01) – Great Abrasion Resistant & Ultra Light Fire Fighting Clothing

Sections

Send A Fire Retardant Clothing Inquiry

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Exhibitions

INTERSCHUTZ 2015

Date: June 8-13, 2015

Booth: Hall 012 / Stand No. G76

Opening Hour: 9am - 6pm

Venue: Deutsche Messe Hannover

[Read more]

News & Press Release

Visit latest design of fire retardant clothing and fire resistant accessory at Fire India 2013

Visit Quality Fire Retardant Clothing at A+A

Visit fire protection clothing supplier at China Fire

Taiwan K.K. Fire Fighting Garment in Nordic Europe

Taiwan K. K. Corp., is a qualified company to supply PPE to fulfill the requirements.

Ready-eSupport

For LIVE HELP... just click "Live Help Desk", our specialists will be with you in air shortly.

Reference

Firefighter Turnout Gear NFPA 1971 Standard (new edition)

Structural Fire fighter Uniform EN 469 Standard (new edition)

Share

Related Products